Power supplies with EtherCAT

Experience the power of real-time application data provided by PULS power supplies with EtherCAT interface.

600 W

Field Power Supply with EtherCAT

Input: AC 380 - 480 V

Output: 24 V, 25 A

4 eFused outputs

M8 A-Coded

IP65/67

Coming soon

Easy. Efficient. EtherCAT.

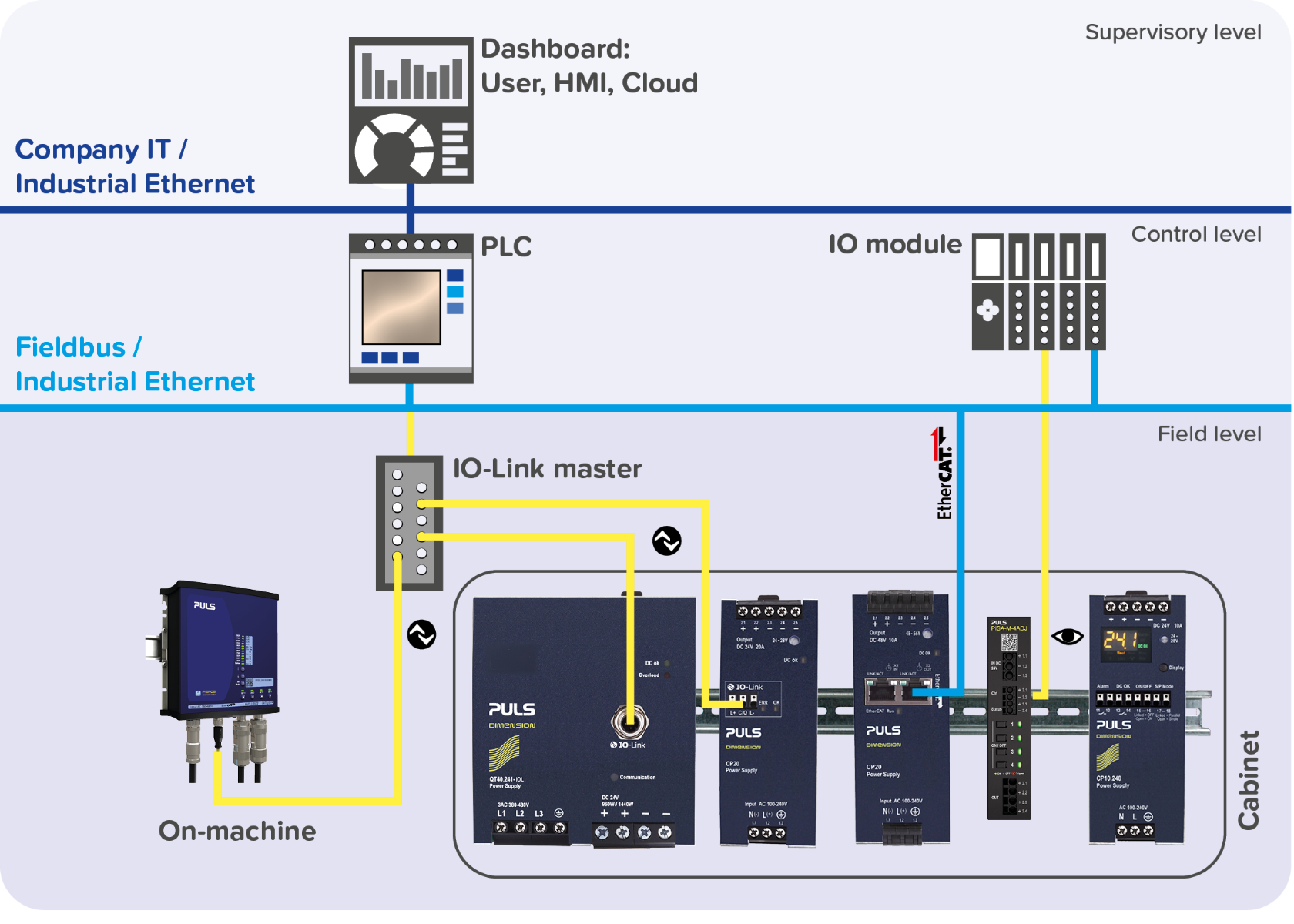

Application data in real-time

PULS power supplies with integrated EtherCAT ports can be directly connected to EtherCAT controllers – without the need for additional gateways, providing easy and rapid access to all application data and power supply functions. The real-time capabilities and high-speed transmission of EtherCAT is ideal for condition monitoring, logging, maintenance and remote in large-scale systems.

The power supply data can also be used within real-time control loops. Based on the data, drives or other high-energy users can be controlled in an optimal way to keep the dynamic power needs within the capabilities of the power supply system. This enables improved system efficiency as power supplies can be used at the optimal operating point.

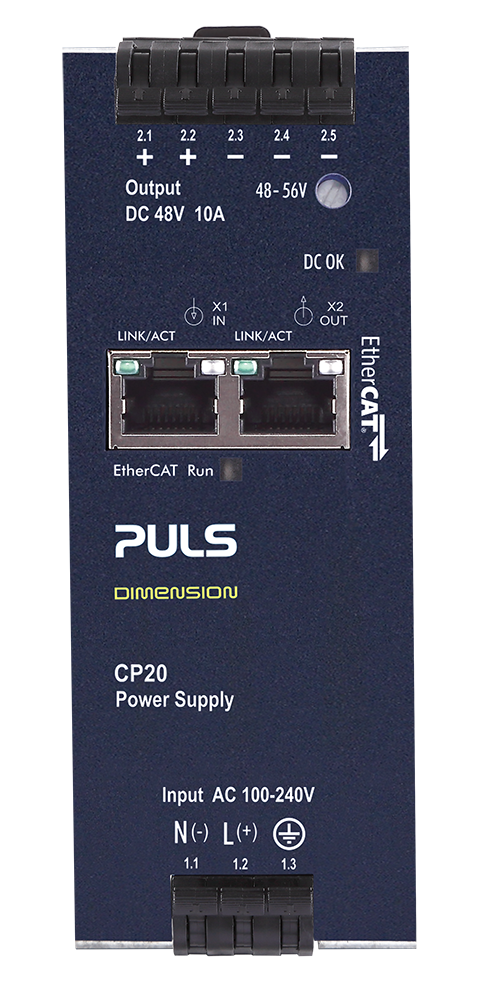

240 W or 480 W

DIN rail power supplies

In: 1-phase | AC 100-240 V, DC 110-300 V

Out: 24 V, 10 A or 20 A; 48 V, 10 A

High efficiency and 48 mm width

Easy fuse breaking

+ 20 % BonusPower (up to +45 °C)

Full power between -25 °C and +60 °C

Order numbers:

, ,

Networking function

2 x RJ45 EtherCAT ports with Link/Activity LEDs

High-speed transmission

Integrated ESI-EEPROM

Your benefits

At a glance

Optimise

your system

Use real application data to improve the utilisation of your system.

Avoid

costly downtimes

Implement preventative maintenance and fix errors before the occur.

Increase

overall efficiency

Reduce energy costs and speed up fault analysis and troubleshooting.

Data potentials

Use cases

Full control of any machine

Smart power supplies with EtherCAT can immediately provide alerts or error messages in case of critical power supply scenarios such as phase failures or transients on the AC-side. This is especially interesting for systems affected by bad AC grid conditions.

In addition, the DC-side can be monitored throughout operation – providing in-time alerts on e.g. power dips or current overloads. This allows a timely reaction by reducing power demands or even entering a safe system status.

Achieve higher energy efficiency and sustainability

Measurement data from AC mains and DC output enables you to monitor and optimize energy consumption. The data provided by power supplies with EtherCAT allow you to reduce operating costs and aligns with sustainability goals, demonstrating commitment to energy efficiency and environmental responsibility.

Enable predictive maintenance

Accessing device and system health data, coming from power supplies with EtherCAT, remotely or on-site allows you to implement predictive maintenance strategies. By monitoring and identifying potential issues before they lead to machine failures, you can reduce unplanned downtime, extend the lifespan of your equipment, and save on maintenance costs.

Enhance productivity

With the real-time data from power supplies with EtherCAT at your fingertips, you can fine-tune machine tool parameters for optimal performance. This leads to increased system throughput, improved product quality, and reduced waste, ultimately benefiting your customers by delivering better results due to the consistent performance and minimal disruptions.

Integration. Quick and easy

Comprehensive documentation

PULS offers all the required documentation and tools to integrate our smart power supplies with EtherCAT into your automation network, enabling direct access to the device data from the PLC or embedded controller.

This includes the download of extensive documentation on our product detail pages – from datasheets, data- and interface-description to quickstart guides, enabling a quick and easy integration.

Deep-dive into application data

Data overview

PULS power supplies with EtherCAT interface provide an extensive set of helpful application data.

Device information

Static

- Vendor ID

- Product Name

- Serial number

- HW and SW version

Realtime

- Device status

- Comm. reliability status

- Stress level

- Internal temperature

Recorded

- Total operating hours

- Internal temperature max .

- Uptime since last turn-on

- Turn-on counter

Input parameters

Realtime

- Input voltage R.M.S. (1 V)

Recorded

- Transient counter

Output parameters

Realtime

- Output current (100 mA)

- Output voltage (100 mV)

Troubleshooting

Events

- Total output current warning

- DC-output voltage warning

- Bonus Power active

- Overtemperature warnings

- Overload warning

- Input voltage out of limits

- Limited remaining lifetime

- Changes via local UI

Remote functions

- On / off

- Remote device configuration

(Vout, alarm limits,

PSU output current warning,

local UI, ...)

*only for FIEPOS field power supplies with integrated e-fuses.

Use your power supply data the right way

Get help from our PULS Application Center

Raw data is worthless if it is not interpreted correctly and concrete recommendations for action are derived from it. Due to the amount of different data available in a system, this step can become complicated.

Our PULS Application Center (PAC) already has decades of experience evaluating and interpreting power supply data. This know-how is available to you at any time. Please feel free to contact our application consultants.

IO-Link. Integrated HMI

Further smart communication options

Smart and independent

IO-Link

IO-Link is used in many machines and can be integrated into various fieldbus networks using IO-Link masters acting as gateways.

PULS provides a range of power supplies with IO-Link interface that allow remote configuration, e.g. output voltage or efuse settings, remote

diagnostics and control.

Local und beneficial

Integrated HMI

Many power supply and supplementary units from PULS are available with an integrated HMI – ranging from simple LED-bars indicating voltages, current settings of e-fuses and output loads to the unique built-in Power Supply Condition Display (PSCD) in the and .

This makes direct monitoring and analysing any application possible.

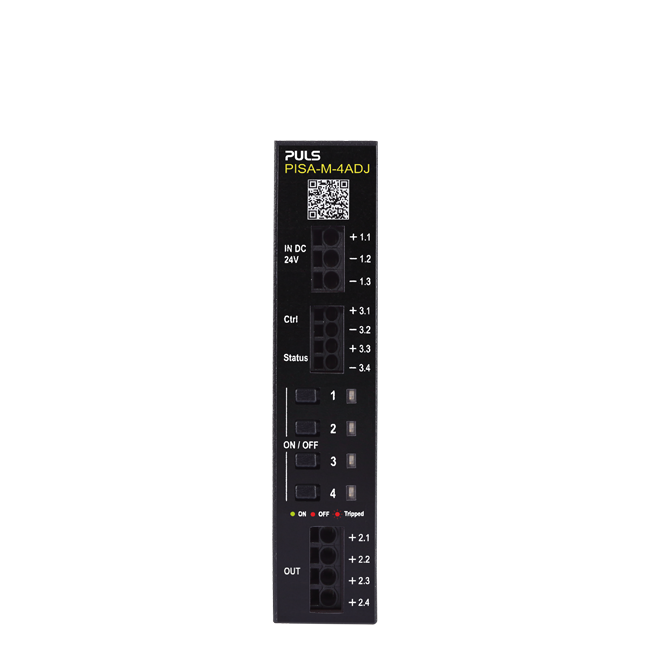

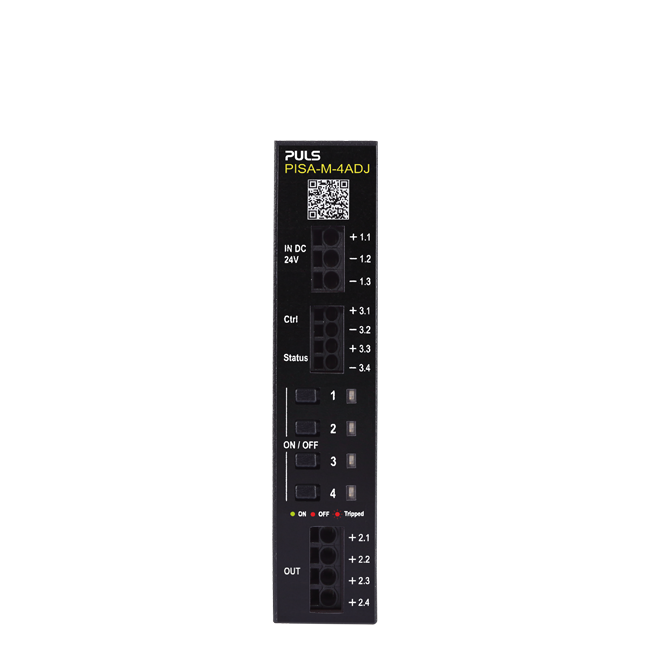

Versatile and robust

PULSbus

PULSbus is a communication link to access to all relevant data of our PISA-M Electronic Circuit Breakers.

This includes voltages, currents, status of the different channels as well as a simple and fast way to configure and even control the PISA-M devices. The PULSbus can be used with basically any control system.